Green Manufacturing from Taiwan Brings Sustainability to Thai Factories: SWAN Integrates Innovation Into Sustainable Air Compressors

Industrial technologies such as air compressors are widely used in modern manufacturing, with key challenges often centered around energy consumption and operational efficiency. These factors have become critical to maintaining competitiveness and achieving sustainable cost reduction in industrial applications. But how can factories adapt and choose the right air compressor technology to meet these challenges, especially in today’s era of uncertainty?

To help shed light on this transition and the evolving challenges of modern air compressors, Mr. Preeda Limpchanapa, Branch Manager at Swan Siam Corporation Co., Ltd. (WHA Office)—responsible for marketing and sales of screw-type air compressors under the Taiwanese brand SWAN—shares his insights with readers of MMThailand today.

When the True Cost of an Air Compressor Lies in Its Electricity Usage – How Should Business Owners Evaluate for Sustainability?

“Did you know that the purchase cost of an air compressor accounts for only 15–20% of its total lifetime cost? In contrast, 75–80% of the cost comes from long-term electricity consumption, and only about 5% is from maintenance and repair,” explains Mr. Preeda. “This shows that the major cost of operating an air compressor lies in the electricity used. Therefore, selecting a high-efficiency, stable air compressor can help reduce energy usage, extend the machine’s lifespan, and minimize the risk of unexpected downtime. This enhances a business’s ability to remain competitive and sustainable in today’s uncertain world.”

The transformation of manufacturing competitiveness today is being impacted globally—from geopolitical and economic pressures to international policy shifts, particularly in the areas of climate change and carbon management at the factory level. Mr. Preeda offers his perspective on how businesses can respond:

“In truth, every business owner brings unique expertise to their own industry, and many are facing immense challenges on both geopolitical and economic fronts. Still, change is inevitable. The key to staying competitive lies in being open to change and adapting as quickly as possible—especially by embracing new technologies. Only then can a business grow and expand sustainably.”

Elevating Air Compressor Sustainability by Integrating Innovation and Intelligent Ecosystems

In today’s manufacturing world, the use of air compressors and compressed air systems focuses heavily on efficiency and cost—factors directly tied to a business’s sustainability and competitiveness. With more than 70 years of experience, SWAN deeply understands the evolving needs of manufacturers, leading to the development of innovations that integrate core air compressor technologies with surrounding and supporting technologies.

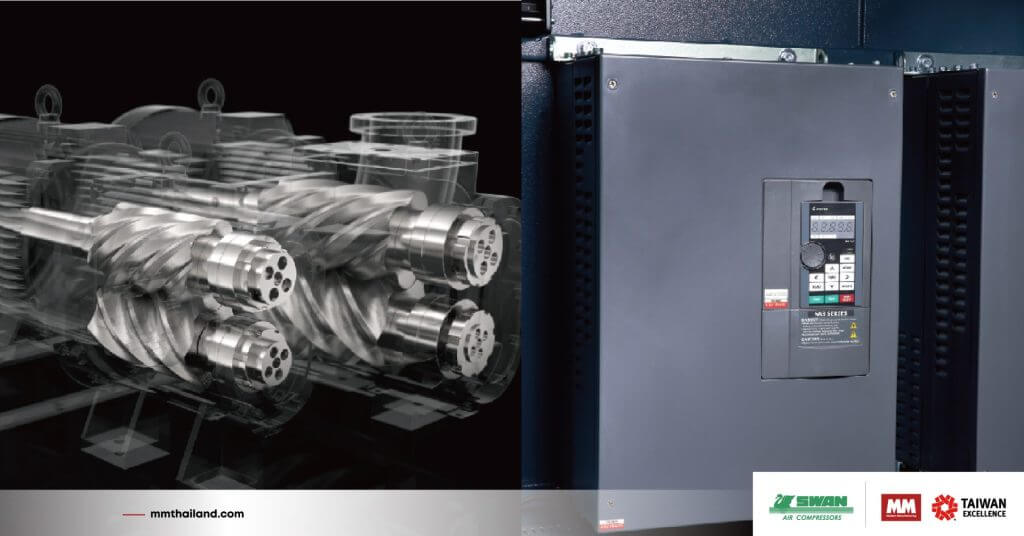

“The challenge for factories today is the initial cost when upgrading to energy-efficient or intelligent air compressors, which requires additional investment. However, in the long term, such upgrades elevate a factory’s competitiveness and support business growth through energy savings and performance improvements. One key technology is the Variable Frequency Controller, which adjusts the compressor’s motor speed according to the actual compressed air demand, thereby reducing energy loss during low-load periods,” explains Mr. Preeda.

Another important advancement is the integration of IoT systems to monitor air compressor operations in real time via cloud platforms. This enables analysis of run-time data and power consumption, allowing for performance optimization and predictive maintenance planning. Alerts for irregularities and service schedules also help minimize downtime. Mr. Preeda highlights that these technologies look beyond the compressor itself, recognizing the importance of the broader ecosystem in Industry 4.0 manufacturing environments.

From an industrial-grade air compressor perspective, energy efficiency and operational performance are key areas of ongoing development. Another notable innovation is the oil-free air compressor. “The oil-free air compressor was developed to meet the rising demand in food and pharmaceutical industries for oil-free compressed air in production processes, while also aligning with environmental concerns,” says Mr. Preeda.

It is clear that integrating variable speed control technology, IoT-based real-time monitoring, and oil-free compressor systems enhances operational efficiency, minimizes unnecessary resource use (especially oil), and supports accurate carbon tracking. These technologies also create transparency across compressed air system activities and enable timely responses—eliminating waste caused by delays or undetected leaks within the system.

SWAN Drives Sustainable Manufacturing Through Innovation, Quality, and Social Responsibility

“At SWAN, we believe that air compressors are not merely machines used in manufacturing processes—they should play an essential role in sustainability, particularly in terms of energy efficiency and environmental impact,” emphasizes Mr. Preeda, highlighting the company’s mission to deliver value through competitive sustainability.

The SWAN brand is operated by Tong Cheng Iron Works Co., Ltd., a company with over 70 years of expertise in producing and distributing air compressors. The company pays close attention to every aspect of the process—from design and mold making to precise production and processing—and is certified by Germany’s TUV ISO9001 and CE standards from the European Union. It also offers both ODM and OEM services to meet customer-specific requirements. The company continuously develops and tailors its products in response to real user needs, with training courses and seminars aimed at advancing industrial capabilities. SWAN’s high-quality air compressors can be experienced at top international exhibitions, connecting the company to manufacturers worldwide.

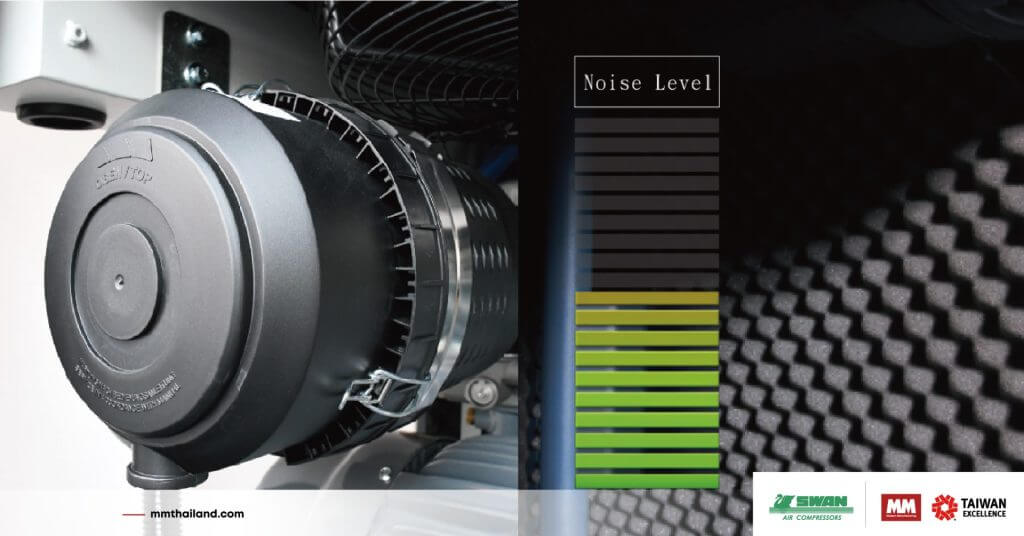

“SWAN has been in Thailand for almost 30 years. We’ve always approached business by understanding our customers’ perspectives. Our company is committed to simple design, stability, and durability. That’s why we’ve built a strong design team and a professional maintenance team, which has earned our customers’ long-standing trust in the SWAN brand,” Mr. Preeda explains. With this understanding of the market, SWAN has developed products that meet diverse customer demands—such as the TMV/TS-MV screw compressor series equipped with Variable Frequency Controllers and Permanent Magnetic Coaxial design for energy saving and low-noise operation, IoT-integrated compressors, and oil-free screw or piston compressors like the AAVD/SDU series, which prevent oil mist contamination in the compressed air.

SWAN has also developed its own SWAN IoT system, which monitors power consumption, compressor temperature, pressure, and maintenance intervals. Users can review historical energy data, and if an IoT-equipped SWAN compressor encounters a fault, the system will send real-time alerts via communication platforms such as LINE or email. This ensures immediate problem resolution. Clearly, SWAN is fully committed to end-to-end innovation that aligns with the evolving needs of industrial manufacturers.

TS-11MV from SWAN: A Screw-Type Air Compressor Designed for Energy Efficiency and Noise-Free Operation

To meet the demand for air compressors that deliver both sustainability and performance, SWAN has developed the TS-11MV screw-type air compressor. This model features a Variable Frequency Controller (VFC), which significantly reduces energy consumption. It is also designed for low-noise operation, making it ideal for use in small-scale factories where noise pollution is a concern.

Of course, TS-11MV is not limited to small factories alone. It integrates seamlessly into automated manufacturing systems through the combination of VFC and IoT technologies, enabling real-time motor speed adjustments based on actual air demand. This ensures precision control within smart factory ecosystems, instant data access, and reduced current spikes during startup—contributing to a longer operational lifespan.

Experience Industrial Air Compressor Innovations from SWAN at MANUFACTURING EXPO 2025

For manufacturers seeking durable, cost-effective, energy-efficient, and fully sustainable air compressor solutions, the SWAN TS-11MV will be on full display. Attendees can see the actual unit and test its capabilities at the TAIWAN EXCELLENCE PAVILION during MANUFACTURING EXPO 2025.

“I would like to invite everyone to experience various aspects of production firsthand, and to meet the SWAN team and experts who can help solve your factory challenges. We’ll provide guidance on how to optimize your compressed air systems—an essential process across nearly all industries—enhancing your competitiveness through sustainable practices and helping you transition toward green manufacturing, which is increasingly critical in today’s global landscape,” concludes Mr. Preeda.

Don’t Miss Out! If you’re seeking an industrial air compressor that supports automation, saves energy, and promotes long-term sustainability, come meet SWAN and see the TS-11MV in action at the TAIWAN EXCELLENCE PAVILION, Booth No. 8F11, within the ASSEMBLY & AUTOMATION TECHNOLOGY zone at MANUFACTURING EXPO 2025, held at BITEC Bangna from June 18–21, 2025, from 10:00 AM to 6:00 PM. Admission is free!

“Discover sustainable machining solutions that are smart, safe, and truly future-ready. Only at Manufacturing Expo 2025.”

- หน้า:

- 1

- 2