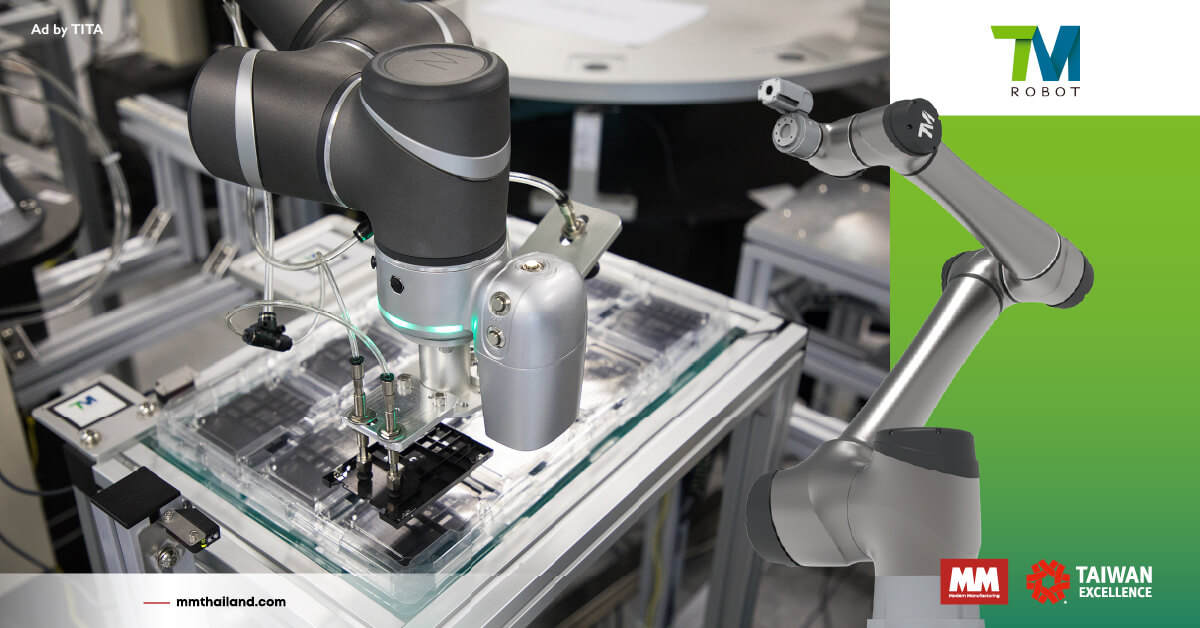

Green Manufacturing From Taiwan Delivers Sustainability to Thai Factories: How Will AI-Powered Cobots From TM Robot Transform Manufacturing?

Over the past three years (2023–2025), the collaborative robot (cobot) market has grown rapidly. In Thailand, this trend is evident at industrial trade shows, where more than 50% of applications now feature cobots. Their ease of use, safety, and increasingly diverse capabilities have fueled this growth. These developments have led to cobots being further enhanced with AI specifically designed for industrial use. But how exactly will AI transform the way cobots are used? Let’s find out from the experts at Techman Robot.

When it comes to cobots, there are a few well-known global brands that typically come to mind. Among them is Techman Robot (TM Robot), which has stood out in recent years for offering a high return on investment and excellent adaptability. In this feature, Mr. Scott Huang, Chief Operating Officer of Techman Robot and part of the company since its founding 10 years ago, shares his insights on how AI is revolutionizing collaborative robotics through real-world applications.

Cobots Are Already Safe and Versatile—Why Do We Still Need to Integrate AI?

According to data from the Association for Advancing Automation (A3), cobots accounted for 11.6% of total robot orders and 6.8% of revenue in Q1 2025. Meanwhile, IDTechEx predicts that the cobot market will grow at a compound annual growth rate of 22.8% over the next 20 years, highlighting a rising trend in cobot adoption. But why exactly are cobots becoming so prevalent?

Industrial Robots Are Complex, Expensive, and Challenging to Use.

“One of the biggest challenges in today’s manufacturing world is the increasing complexity of production, which can quickly become overwhelming. Combined with labor shortages, it can halt competitiveness in some businesses. This puts manufacturers under pressure to deliver higher output while maintaining consistent quality. That’s why factories must become smarter,” said Scott.

Traditionally, using robots and automation systems required specialized skills that take time to acquire—like coding for process control and integrating various technologies from different vendors, each with its own communication protocol. Some brands are even closed systems, making integration even more difficult.

Additionally, industrial robots often require safety measures such as cages, motion sensors, and emergency stop systems due to their large size and high-speed movement, which can pose serious safety risks. Therefore, industrial robots are typically part of a larger ecosystem involving PLCs, networks, control units, safety devices, custom software, and end-of-arm tooling (EoAT). Because of these numerous dependencies, traditional industrial robots offer limited flexibility in the face of change.

These limitations led to the development of cobots—robots designed to be more adaptable and sustainable for modern business needs.

Cobots: True Allies of Entrepreneurs and Workers in the New Era of Manufacturing

The origin of cobots came from the need to address longstanding challenges manufacturers face when using traditional industrial robots. One of the most notable features is that cobots can operate without needing safety barriers, enabling them to work closely alongside humans. They are equipped with force-detection sensors that can automatically stop motion, and their lightweight structure reduces the risk of serious injury from collisions or errors during operation.

Moreover, cobots require a much smaller ecosystem for deployment compared to industrial robots. Most cobots come as ready-to-use Plug & Play units, requiring minimal investment. They are easy to install and highly customizable. Users can program tasks through a pendant using simple teaching interfaces, and newer cobot models allow drag-and-drop programming via visual icons to configure work sequences quickly. This means no specialized skills are required—anyone familiar with general technology use can operate them, offering a high degree of flexibility.

It’s clear that cobots are relatively low-cost compared to conventional industrial robots. At the same time, their ease of use and the simplified setup—spanning configuration, task design, and safety—make them suitable for either standalone applications or integration into broader automation systems. They also complement human workers rather than replace them, which differs from traditional automation that often sidelines labor. cobots work alongside people to combine the strengths of automation with human creativity and problem-solving—making them a sustainable and practical solution for modern factories.

AI Transforms Automation Into Intelligent Operations

“Although the operation of cobots already significantly elevates performance compared to traditional industrial robots, it still requires human experience to design various processes,” said Scott. “You could say it’s a form of automation that’s highly accessible. But when AI is added to the mix, it transforms this automation into true intelligence—creating a different level of user experience and competitive potential.”

“At Techman Robot, we believe the answer to modern manufacturing challenges lies in intelligent automation. That’s why our development of cobots always includes integrated AI working in tandem with a vision system—both standard in every robot model we produce. This integration enables not only highly precise and efficient task execution but also the ability to recognize, adapt, and evolve in real time. It allows manufacturers to apply automation to even complex workflows with ease, while reducing waste from human limitations and boosting efficiency without compromising product quality,” explained Scott, sharing Techman Robot’s perspective on applying AI within their cobot development.

Techman Robot Opens the Door to Smart Manufacturing for All with AI + Cobot

“We aim to bridge the gap between traditional automation and intelligent systems by integrating AI, vision technology, and cobots into a single platform. This allows manufacturers to access comprehensive solutions for key challenges such as quality control, flexible production, and labor shortages—without the need for complex programming or integration processes.

With deep understanding of both technology and real-world production needs, Techman Robot collaborates closely with expert teams and partners to ensure our solutions are easy to implement, adaptable, and aligned with each customer’s business goals,” said Mr. Scott, explaining the core of Techman Robot’s technology development philosophy, which puts user challenges first.

Anyone familiar with Techman Robot’s products will recall that every TM Robot-brand comes with a built-in vision system. Some may wonder if this is excessive or why a camera system is necessary and not optional. Mr. Scott addressed this clearly:

“Our machine vision technology is one of the reasons we stand out. By integrating cameras into the robot design from the outset, our cobots can quickly and effectively respond to new production challenges. Because the system is designed to work with vision natively, there’s no need to worry about complex future integrations or system failures. Our AI cobot is an all-in-one solution that combines robotic arms, vision systems, and AI algorithms into one platform. Unlike conventional setups that require separate purchases from various vendors, Techman Robot’s AI cobot includes everything—reducing time, cost, and engineering burden. This creates a clear competitive advantage.”

As you can see, the integration of AI + cobot from Techman Robot has been designed from the ground up to work seamlessly together at both the conceptual and system level.

AI Cobot Series and Flying Trigger from Techman Robot: Smart Solutions that Enhance Agility in Modern Manufacturing

“The highlight of Techman Robot’s AI cobot is faster installation, easier maintenance, and convenient long-term upgrades. Customers no longer need to guess who to contact when problems arise—we take full ownership of the solution and offer single-point-of-contact service throughout the product lifecycle. This reduces complexity, lowers risk, and delivers strong ROI. We’re proud to bring some of our award-winning technologies, recognized by TAIWAN EXCELLENCE, to Thailand for manufacturers to try firsthand at Manufacturing Expo 2025,” Scott highlighted the business management benefits of their latest generation of intelligent cobots. These innovations will be showcased at upcoming events for attendees to experience firsthand.

AI Cobot Series

Techman Robot’s intelligent cobots come equipped with built-in vision systems and AI, ready to use out of the box. They support a wide range of applications—such as pick-and-place, AMMR integration, welding, and quality inspection. These cobots are bundled with AI libraries tailored to specific industries like electronics, automotive, and logistics. Pre-trained templates are available for each use case, and parameters can be adjusted to suit specific business needs, allowing users to get started quickly and maintain competitive consistency.

“I’d like to highlight our robots in Jinpao Precision’s facility in Thailand, which manufactures high-precision components for the automotive, aerospace, and other sectors. Known for their strict quality standards and advanced engineering, Jinpao integrated AI-based automation to reduce human error, deploying our TM5S, TM12S, and TM25S models in various tasks such as pre-shipment inspection, in-process quality control (IPQC), and surface defect detection. All of these robots are AI cobots that combine vision, AI, and motion control into a single platform, reducing the need to coordinate between multiple vendors for robots, AI software, and vision systems. This simplified setup enabled faster deployment, reduced engineering complexity, and streamlined after-sales service, delivering efficiency across the board,” Scott explained with a real-world case from Thailand.

Flying Trigger Solution

Techman Robot has combined its advanced Flying Trigger inspection technology with AI, enabling real-time quality control even while parts are in motion—eliminating inspection-related downtime. This can reduce inspection times by up to 50%, significantly improving cycle time and OEE. Example applications include seat assembly in the automotive industry or server assembly in the electronics sector.

Experience Out-of-the-Box Smart Robotics from Techman Robot—Only at Manufacturing Expo 2025

“What sets our AI apart from general-purpose AI that requires integration with multiple software and hardware platforms is that our AI works seamlessly with our robots—right out of the box. Users can train models for defect detection, object recognition, and pattern classification without writing any code or needing advanced programming skills. We invite you to visit Techman Robot at Manufacturing Expo 2025 to experience how our AI cobots and Flying Trigger technology are redefining quality, speed, and flexibility on the production floor. Let’s build the future of smart manufacturing together!”

Don’t miss it! Manufacturers looking to upgrade their production capabilities—especially with cobots—can’t afford to miss the AI cobot and Flying Trigger Solution from Techman Robot. Experience it live at the TAIWAN EXCELLENCE PAVILION, Booth 8F11, in the ASSEMBLY & AUTOMATION TECHNOLOGY zone at Manufacturing Expo 2025, BITEC Bangna, from June 18–21, 2025, 10:00 AM–6:00 PM. Entry is free!

“Discover sustainable machining solutions that are smart, safe, and truly future-ready. Only at Manufacturing Expo 2025.”

- หน้า:

- 1

- 2