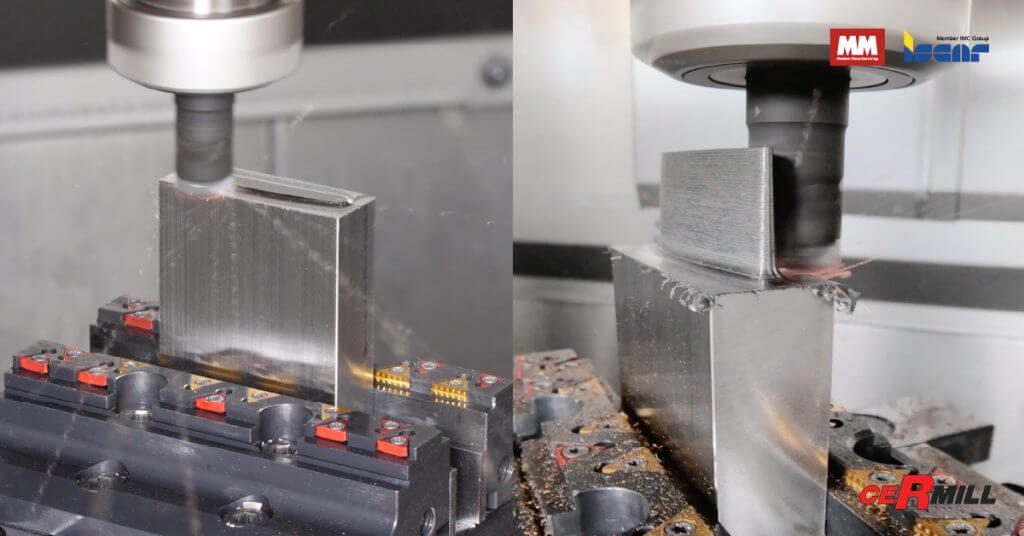

CERMILL, a New Family of Endmills with Ceramic Round Inserts, Provides a User-Friendly Solution For High-Efficiency Machining

ISCAR is introducing an innovative solution to boost productivity in milling nickel-based high temperature superalloys (HTSA) and cast iron with the use of ultra-hard cutting materials: the CERMILL, a new family of relatively small-in-diameter indexable endmills with ceramic round inserts. The key element of the family is an ingenious mechanism of high-rigid

insert clamping, which provides two important advantages:

1. Increased number of teeth compared to existing designs

of similar endmills in the same diameter.

2. Fast, simple, and user-friendly indexing and replacement of the insert,

without the need to remove the endmill from the tool holder

The combination of a higher number of teeth and the extreme rigidity of the clamping mechanism makes the CERMILL an effective tool for boosting productivity in milling operations, particularly, milling planes and 3D surfaces.

The indexable mill design concept in the relatively small tool diameter range offers significant cost-effectiveness compared to the prevailing solid designs within this diameter range.

CERMILL Endmills

In the initial stage, the CERMILL endmills are currently offered in three different diameters: 16 mm, 20 mm, and 25 mm. The endmill bodies feature a special coating that serves two purposes: enhancing chip flow and providing protection against corrosion and wear.

CERMILL Inserts

The endmills carry indexable single-sided positive round inserts in diameter 6.35 mm. The inserts are produced from the following ceramic grades:

• IS14 and IS15 that are intended for machining HTSA,

• IS45, which is designed for machining both HTSA and cast iron.

These inserts are available in various designs depending on the cutting-edge condition.

Application Remarks

Major industrial sectors: Aerospace, Power Generation, Marine Engineering, and Automotive.

Main applications: milling faces, cavities, pockets, complex-shaped surfaces, close-to-shoulder milling, and ramping down including helical and circular interpolation.

Coolant: dry coolant only! The use of wet coolant is prohibited due to its negative impact on performance and the tool life of the inserts.

Tightening torque: 0.7 Nm.

This is the average torque, developed by an operator when using the clamping key, which is included with a tool in the tool packaging box. Optionally a fixed-torque assembly is available, ensuring the application of precise tightening torque. This assembly includes a handle T.WRENCH TBN 2 0.4-2NM and a bit ERP BIT D4-30 mounted on the handle. Both the handle and the bit should be ordered separately.

Contact for More Detail :

ISCAR (Thailand) LTD.

Website: www.iscarthailand.com

Address: 57, 59, 61, 63 Soi Samanchan-Babos, Sukhumvit Rd, Phra Khanong, Khlong Toey, Bangkok 1011

Sales Office Tel: +66 2713 6633-5

Tel: 081 564 3789 – Mr. Jarupong (Sales Manager)

Fax: +66 2713 6632

- หน้า:

- 1

- 2