Green Manufacturing from Taiwan Brings Sustainability to Thai Factories: Reducing Robot and Automation System Costs with UP Xtreme 7100 Edge

With the rapid transformation of global supply chains, increasing geopolitical uncertainty, escalating environmental risks, and the aging population crisis, achieving sustainability in business—especially in manufacturing—has become a major challenge. One of the key approaches adopted by manufacturers worldwide is investing in new technologies such as digital systems, robotics, and automation to respond to these evolving challenges. But for Thailand, where the majority of the industrial sector has yet to reach Industry 3.0, how should businesses adapt? Mr. Brian Tsai, Sales Director at AAEON and an expert in AIoT for the manufacturing sector, invites readers to explore possible answers.

When the key challenge in manufacturing is finding the balance between competitiveness and sustainability

“What we observe in today’s manufacturing sector is that producers are under increasing pressure to adapt and to develop competitiveness with a longer-term vision. This means that businesses must strive to stay competitive while also committing to sustainability across various dimensions,” says Mr. Brian Tsai, reflecting on the continuous and complex challenges faced by modern manufacturers.

From Global Challenges to the Impacts on Thai Manufacturers

As most of Thailand’s industries operate under OEM manufacturing models, one of the most major challenges they now face is the trade uncertainty and policy shifts caused by ongoing geopolitical tensions, which have significantly impacted the manufacturing landscape. At the same time, it has further accelerated the relocation of production bases—a trend that had already begun during the COVID-19 pandemic. In recent years, global supply chains have undergone extensive restructuring, compelling companies worldwide to re-evaluate their operational strategies and industrial footprints in order to enhance competitiveness and resilience in an increasingly complex and rapidly evolving global environment.

At the same time, environmental urgency continues to grow, leading to the implementation of carbon regulations and economic instruments like CBAM (Carbon Border Adjustment Mechanism). These measures are designed to manage the environmental impact of industries—especially those with high resource consumption. Crucially, these frameworks don’t just evaluate emissions during the manufacturing process, but also account for the entire supply chain, making every detail and data point a cost driver for the business.

Both domestic and international experts agree that integrating modern technologies can mitigate many of the risks brought on by this uncertainty. By combining digital solutions with advanced operational technologies—such as robotics and automation systems that form part of Industry 4.0—manufacturers can transform their operations. Technologies like AI and edge computing are reshaping the industrial landscape entirely. However, in Thailand, the overall adoption of industrial automation technology still lingers around Industry 2.0 levels, only now beginning to approach Industry 3.0 (based on the Thailand i4.0 Index). As a result, transformation efforts are ongoing, but it’s clear that not every factory investment leads to success.

“Enhance the right areas, integrate what fits your business” – AAEON’s Answer to Modern Transformation

“For Thailand to successfully transition toward Industry 4.0 manufacturing technologies, it is essential to first understand the core principles of Industry 4.0,” says Mr. Brian Tsai, outlining the fundamental considerations for Thai manufacturers seeking to modernize or invest in new systems.

- Increasing production efficiency and flexibility

- Reducing operational costs and dependency on human labor

- Enhancing real-time quality control and decision-making

- Supporting mass customization with low-volume, high-variety production

- Building smart factories

In the journey toward business and factory transformation, Mr. Tsai emphasizes the importance of first identifying the most critical pain points and selecting technologies that directly address real-world challenges. This entire process should be grounded in the core principles of Industry 4.0.

AAEON, a member of the ASUS Group, leverages its robust customization capabilities to deliver practical and scalable solutions tailored for smart manufacturing. By collaborating closely with clients, AAEON’s expert team begins with a deep understanding of each business’s unique needs and pain points, enabling them to deliver precise, impactful solutions. This customer-centric approach empowers enterprises to navigate transformation with confidence and accelerate their path toward intelligent, data-driven manufacturing.

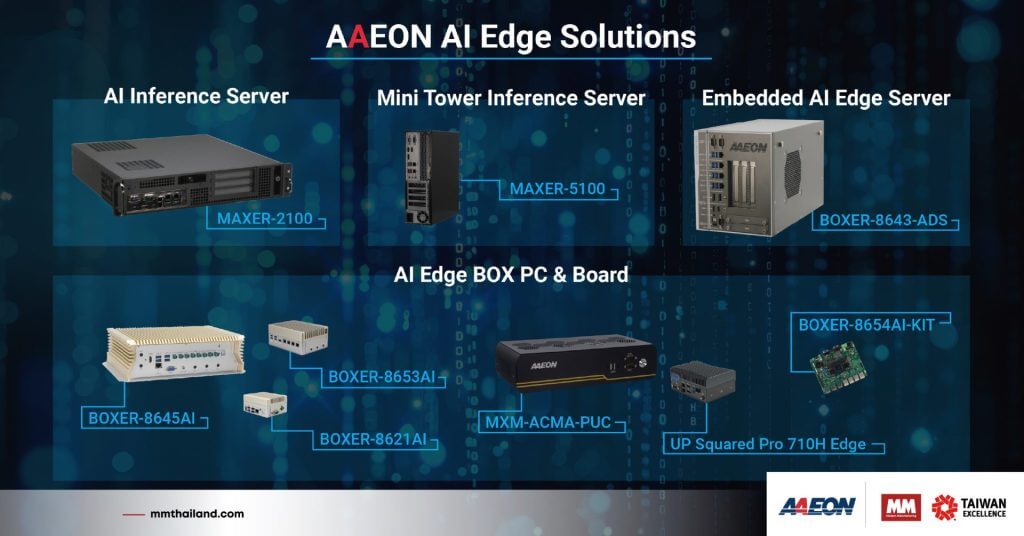

AAEON: The Smart Factory and Robotics Partner in the Era of Sustainable Manufacturing

AAEON, or AAEON Technology Inc., is a company with expertise in Industry 4.0, industrial computing, and edge AI for intelligent IoT, covering both design and manufacturing. The company was founded in 1992 in Taiwan and became a part of the ASUS Group in 2011—a globally recognized brand in computers and IT. AAEON has worked closely with global technology leaders such as NVIDIA, Intel, AMD, Hailo, and NXP, which has resulted in a wide range of AI Edge platforms tailored to various industrial sectors, with a deep understanding of the challenges they face.

“Our strength at AAEON lies in our customization capabilities, which allow us to design industrial computers tailored to a wide variety of application needs,” says Mr. Brian Tsai. “We also collaborate with leading global tech companies, enhancing our technical expertise, customer support, and continuous innovation. This results in truly outstanding manufacturing expertise.”

Digital Twin Integration

AAEON provides high-performance, reliable AI edge platforms designed to support the deployment of digital twin software and AI applications in factory automation and digital transformation. These platforms serve as the foundation for executing pre-developed digital twin models, enabling manufacturers to monitor, analyze, and optimize production in real time.

By supporting advanced AI workloads and seamless integration with existing system architecture, AAEON’s solutions empower factories to implement predictive maintenance, intelligent process control, and energy optimization—accelerating the shift toward smart, sustainable, and efficient manufacturing environments.

Smart Factory Automation

AAEON possesses deep expertise in AI, robotics, and machine vision technologies—smart solutions that empower automated factories to enhance productivity and maintain consistent quality. These technologies enable real-time waste prevention and optimize machine performance through uniquely capable edge AI. This supports predictive maintenance, anomaly detection, and adaptive process control with high efficiency. Additionally, it effectively addresses labor-related challenges in modern manufacturing environments.

UP Xtreme 7100 Edge: The Industrial Robotics Solution Recognized by TAIWAN EXCELLENCE 2025

For those who value high-quality, cost-effective products, the Taiwan Excellence mark is a trusted symbol that signifies exceptional innovation from Taiwan. AAEON’s UP Xtreme 7100 Edge, a winner of the Taiwan Excellence 2025 award, is an industrial-grade computer specifically designed for use with robotics and automation systems in Industry 4.0 manufacturing.

“In developing robotics systems, clients and system integrators often face the challenge of integrating multiple components, which leads to high costs and extended timelines,” says Brian Tsai.

“To solve this, AAEON collaborated with leading robotics manufacturers to create the UP Xtreme 7100 Edge, an all-in-one solution that combines processing power, 24V DIO, CAN bus, and control functions into a single unit. This minimizes the need for additional parts, significantly reducing costs and enhancing competitiveness.” This highlighted product, designed specifically for applications such as Autonomous Mobile Robots (AMR), Automated Guided Vehicles (AGV), robotic control systems, service robots, medical robots, and collaborative robots (Cobots), represents AAEON’s strategic response to the evolving needs of modern factories.

| Key Features of UP Xtreme 7100 Edge: Integrated and Streamlined Design: Combines processing capabilities, 24V DIO, and CAN bus into a single unit. Cost-Effective: Reduces the need for additional components. Easy Assembly: Saves time and labor with an all-in-one design. Lower Total Cost of Ownership (TCO): Cuts down on long-term maintenance and sourcing costs. Quick Deployment: Ready to use immediately thanks to its integrated solution. High-Volume Production Support: Reliable supply and long-term support. Customizable: Flexible design to meet specific application requirements. |

Experience the Full Potential of UP Xtreme 7100 Edge from AAEON—Only at MANUFACTURING EXPO 2025!

“We understand that many businesses are eager to upgrade and transform, but face a major challenge: where to start, and how to choose the right solution. That’s why the first and most important step is discovering what the customer truly needs,” says Brian Tsai. “AAEON offers a wide range of solutions for smart factories—ranging from robotics systems, conveyor systems, industrial gateways, to security systems—especially in the area of cybersecurity. We are confident that these advanced platforms will elevate Thailand’s manufacturing sector not only in terms of operational efficiency and automation but also in energy and resource conservation. These are the keys to environmentally responsible production.”

“No matter if you’re a robotics manufacturer, a company seeking to expand flexible AI applications, or a business in a niche market, our diverse range of solutions is designed to meet your specific needs—whether you’re a small, medium, or large enterprise. We warmly invite everyone to discover how AI can empower your journey toward sustainable manufacturing. We look forward to welcoming you at the TAIWAN EXCELLENCE PAVILION during MANUFACTURING EXPO 2025.”

Don’t miss out! Manufacturers interested in edge solutions for smart factories and next-generation industrial robotics can meet with AAEON and experience the UP Xtreme 7100 Edge firsthand at the TAIWAN EXCELLENCE PAVILION, Booth No. 8F11, in the ASSEMBLY & AUTOMATION TECHNOLOGY zone at MANUFACTURING EXPO 2025, held at BITEC Bangna from June 18 to 21, 2025, between 10:00 AM and 6:00 PM. Admission is free!

“Discover sustainable machining solutions that are smart, safe, and truly future-ready. Only at Manufacturing Expo 2025.”

- หน้า:

- 1

- 2